Products

Company that strive for the development of your National Clamp.

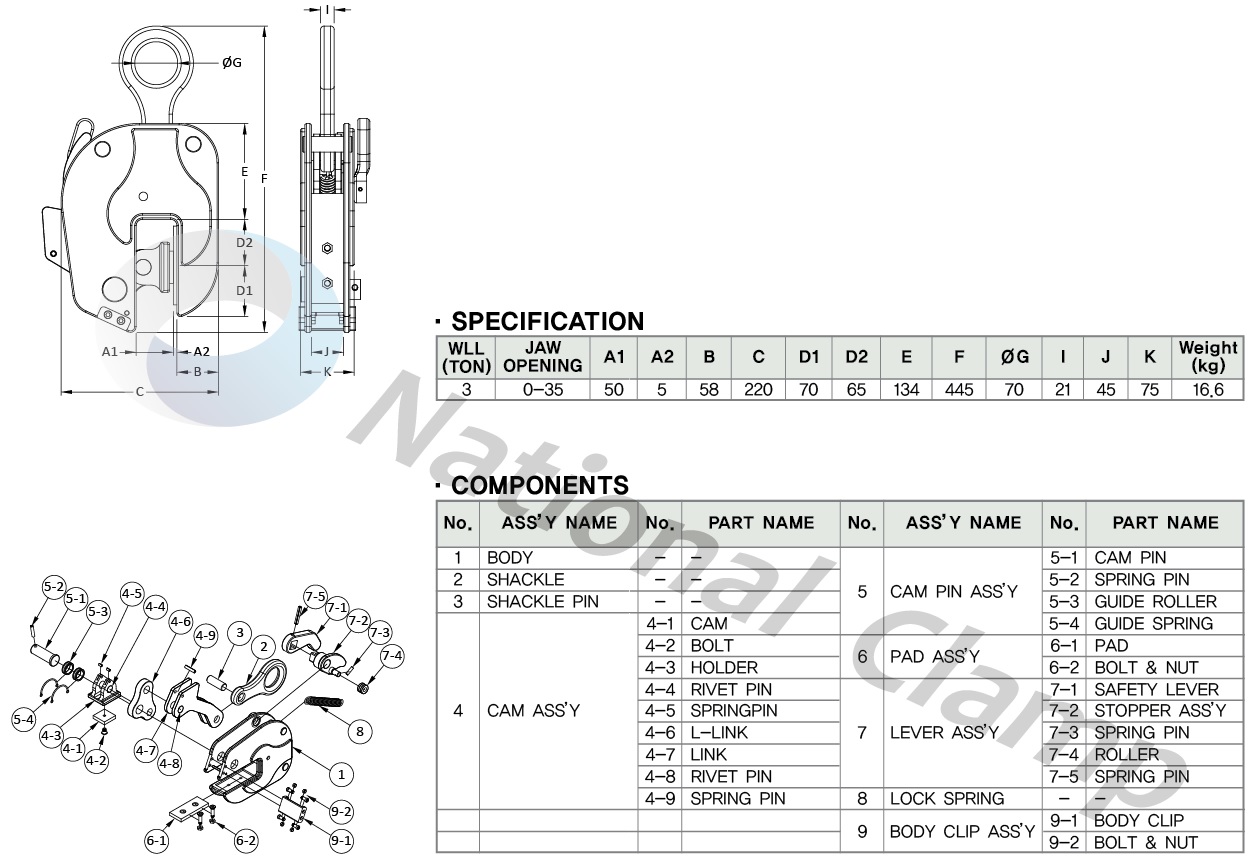

NVC-LPA

· Application

- The NVC-LPA is an upgraded version of the NVC-LP. The NVC-LPA leaves no teeth mark at all, even not the slightest

teeth mark. This model is used to lift materials for building a variety of tanks that store or transport chemical products.

· Features

- The NVC-LPA is designed to vertically lift nonferrous metals(stainless steel and aluminum) which are usually used for

building LNG ships or plants at shipyards.

- The NVC-LPA is designed to maintain strong clamping force as the cam is pinned by the L-shaped link.

- The NVC-LPA is a specially designed clamp whose cam and pad do not have teeth and are made of special aluminum,

leaving no teeth mark at all on a work piece.

· How to use

- Insert a work piece into the inside end of the clamp's jaw opening and then fasten the safety lever.

- Clamp the center of gravity of a work piece in order to equally distribute the weight of the work piece

· Warnings

- Before clamping, remove oil or grease on a work piece with detergent and a cloth to prevent slipping.

- Since the cam and the pad of the NVC-LPA are made of aluminum, they get easily worn out. Therefore, always check

the wear and tear of clamp components before use.

- Do not exceed the rated capacity specified on the clamp.

- Use a work piece only which falls within the jaw opening range specified in the instruction manual.

- Never lift two or more work pieces with one clamp.

- With the NVC-LPA, do not exceed the maximum working angle of the sling wire rope.

- Lift a work piece only after checking the biting location and the biting condition of the work piece, and the proper

functioning of the safety lever.

- When lifting a work piece, a signal man must be outside the rotation radius of a work piece to send a signal to a crane

operator.

PREV

PREV NEXT

NEXT